泡沫夹芯板围挡常用于非市政道路路段的工地,且工地施工时间在2年以内。泡沫围挡的成本相对市政A款围挡低廉,也可以起到施工区与其他区域分隔的作用。现在介绍众润房屋的装配式泡沫围挡的安装工艺流程。

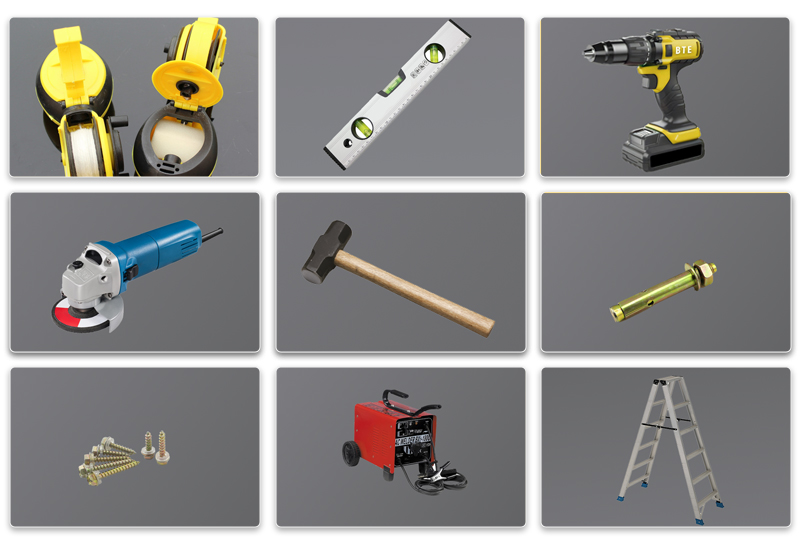

准备工具:墨斗、水平尺、电动螺丝刀、砂轮机、铁锤、冲击钻、M8膨胀螺丝、自攻螺丝、电焊机,人字梯等。

装配式泡沫围挡安装工具

准备工作:围挡的安装地面要求已经硬化的地面,用墨斗弹出预先安排好的安装线路。

安装流程:

- 拼板

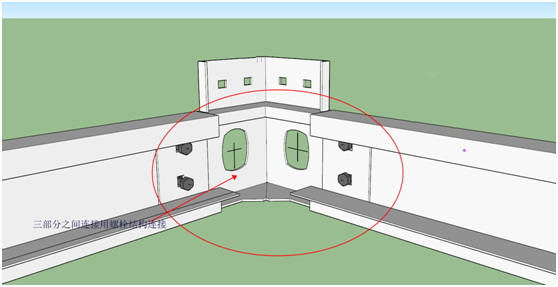

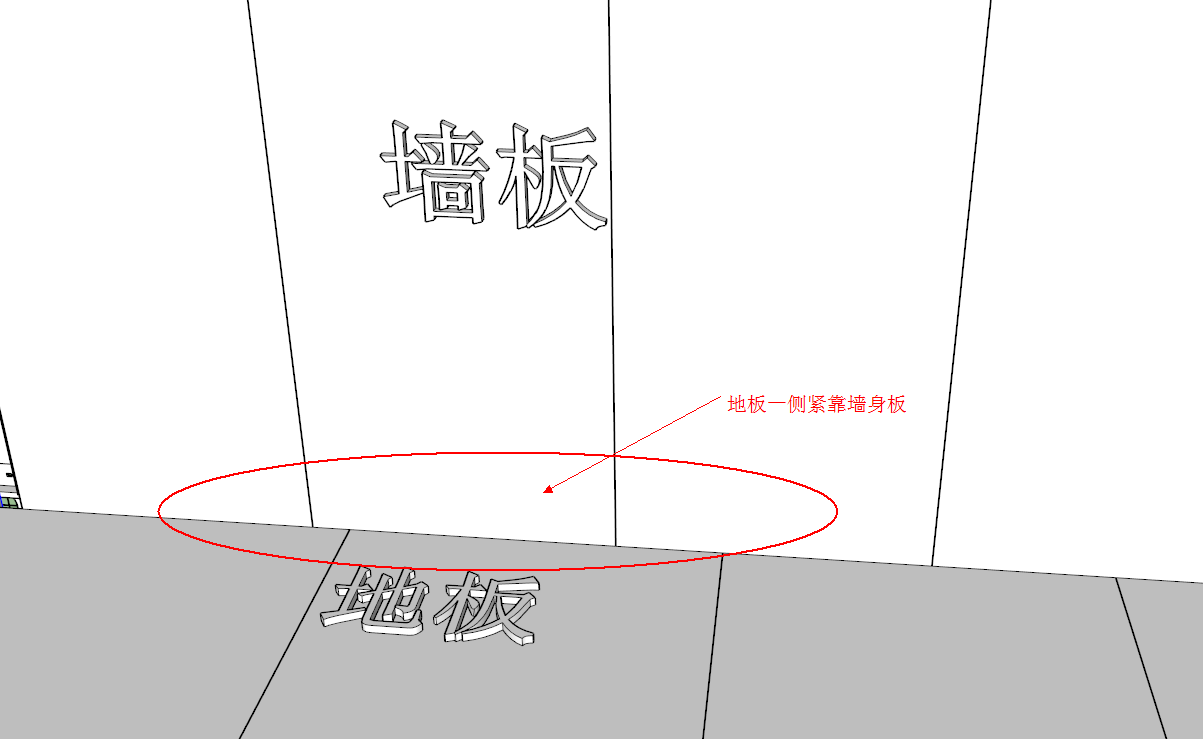

泡沫围挡的宽度一般是3米一档,高度跟进客户需要定制。板材的尺寸是950毫米一张,3张夹芯板拼接一起,上下卡入U型槽。然后用自攻螺丝加固卡槽和夹芯板。

卡槽上下卡住且用自攻螺丝固定后,需要左右两边留出长度约5厘米的U型槽,用于嵌入立柱卡口的受力点。

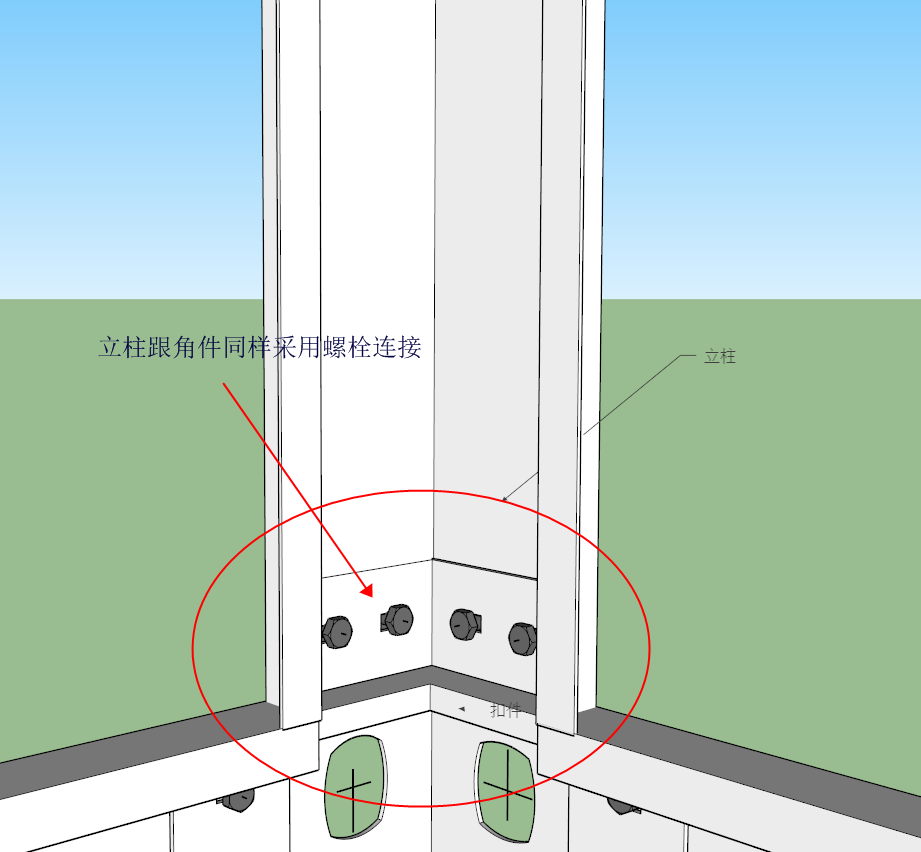

- 安装立柱与墙板安装

在硬化好的地面基础上放置立柱,沿立柱底座的四个孔眼,用冲击钻打孔,然后塞入膨胀螺栓,再用电动螺丝刀把膨胀螺丝刀的螺帽拧紧。接着,把拼板后的2.8m*2.85m墙板上突出的U型槽插入立柱的两侧开口,最后用自攻螺丝前后固定。

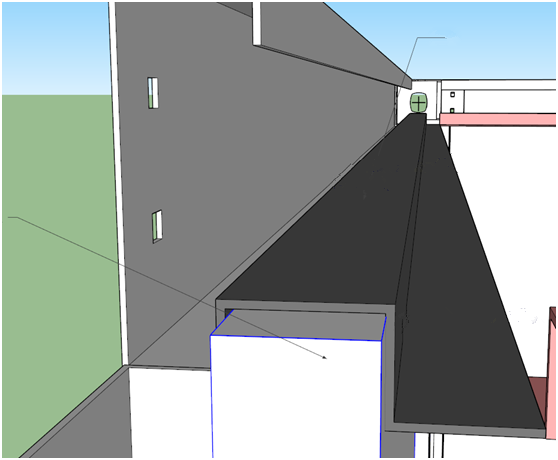

遇到有高低差的地形,需要将U型槽切开三瓣,分别用自攻钉固定在方通立柱柱身上。

- 安装斜撑

在安装立柱的时候,要提前安排斜撑耳朵的位置,不同的地形斜撑的安装方法也需要灵活变通。

- 水泥地面;斜撑没有耳朵一头用自攻钉链接上立柱上的耳朵,打两颗自攻钉固定。地面上,用冲击钻沿斜撑耳朵钻孔,然后用膨胀螺栓固定。

- 斜撑基础为泥地;把长度50cm以上角铁或方通垂直打入泥土里,留出5cm的长度用自攻钉和斜撑固定。

- 靠近脚手架施工区域;斜撑可以通过测量,裁出适合的长度,然后通过自攻钉把斜撑耳朵和脚手架固定在一起。

泡沫围挡的安装方法介绍到这里,希望能对您有帮助。如果需要临时建筑的材料和施工,可以联系众润房屋官网后台客服或留言,我们会在24小时内联系您!

焊机在做工地大门的工序中用到

Container installation guide

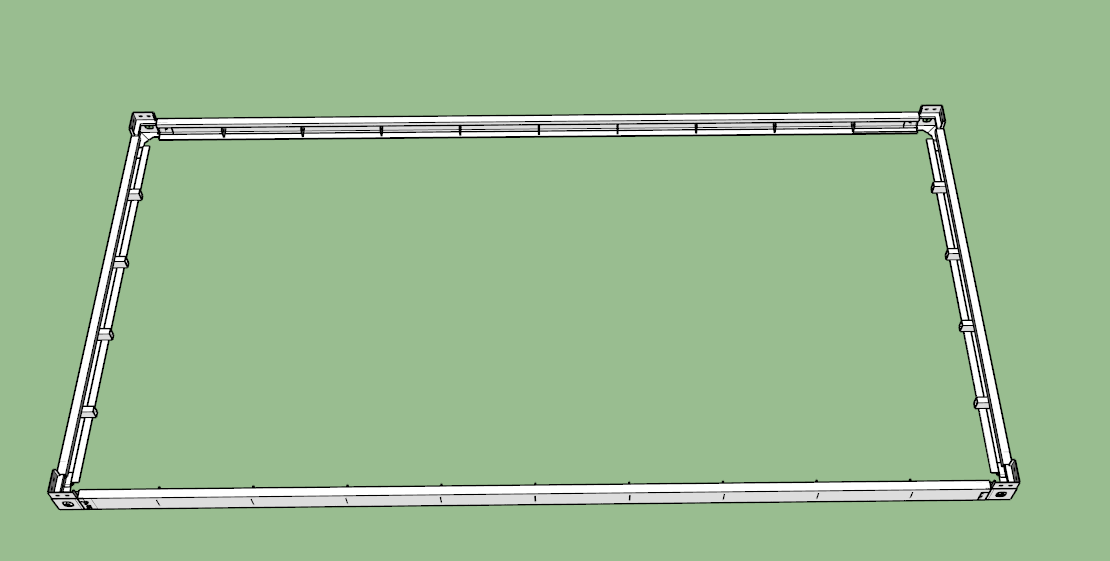

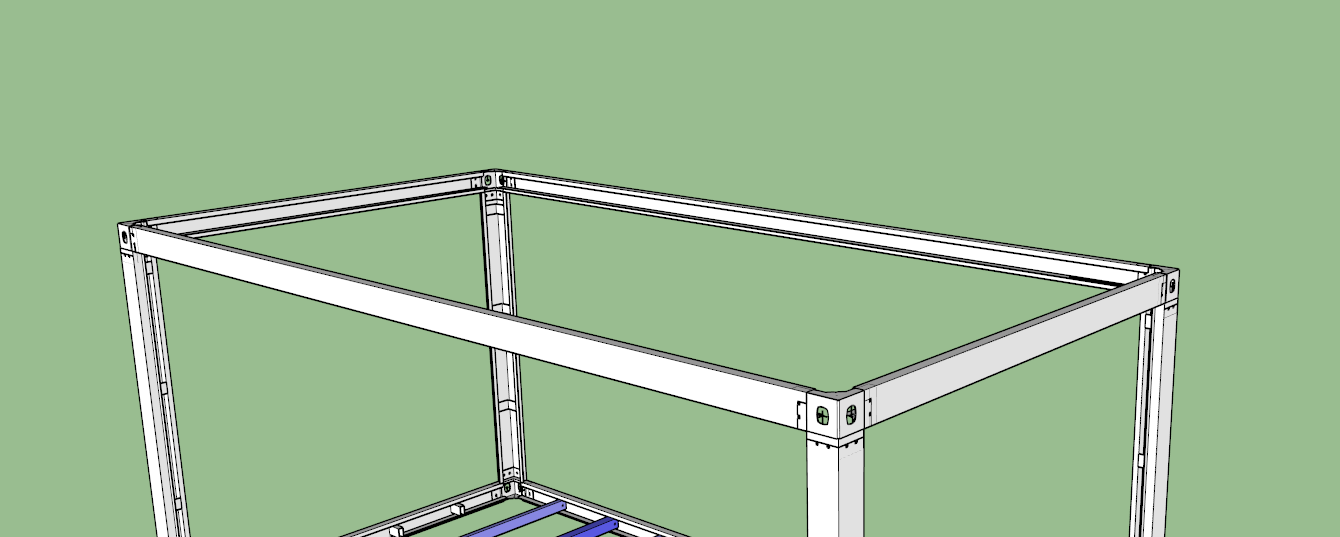

1.Bottom frame assembly, horizontal adjustment

Take 4 beams, 2 bottom side beams and 2 bottom beams, and connect corner Fitting of the base frame with bolt connection.

图1-2

When performing Step 1, adjust the horizontal and diagonal lines, and properly raise the chassis to ensure that the chassis is in the same horizontal position. Note that the bolts do not need to be tightened, but can be tightened manually

After completing Step 1, you can obtain the base frame as shown in Figure 1-2

图1-2

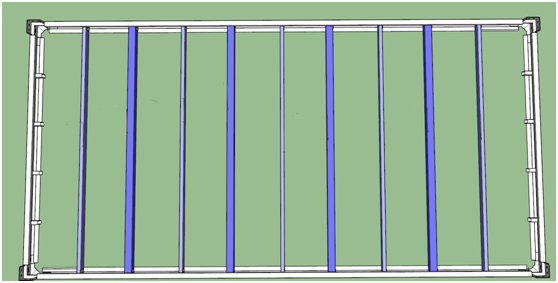

2.Bottom purlin installtion

Ues 4pcs 80*80galvanized steel and 5pcs 40*80galvanized steel , with screws fixed, tighten, two different square pipe distribution position for the way of inter-fault distribution s shown in Figure2-1

图2-1

3.Install Pillar and top frame

Four V-shaped pillars are inserted into the foot pieces of the Corner Fitting, manually linked with carriage bolts, and four link corner pieces are fitted to the top of the posts. Then use a ladder to assemble the top two 5.63m bottom side beams and two 2.68m bottom beam frames onto the top corner pieces and manually tighten the screws. See Figure 3-1 and Figure 3-2

图3-1

图3-2

4. Frame adjustment

Adjust the two sides of the pillars in turn with a level, adjust and hold it, and tighten it with a wrench. So the top frame must be positioned in line with the chassis frame.

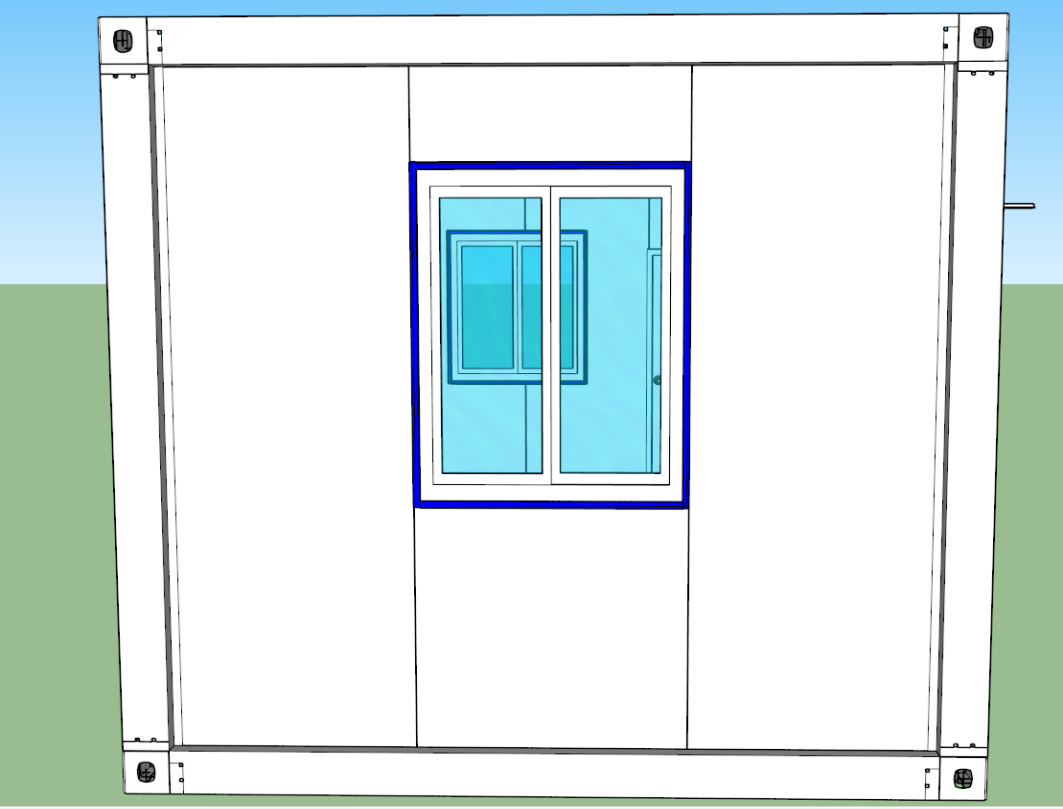

5 . Wall , door and window install

Row the rear wall first. The rear wall consists of two 2.55 panels, a window and a lower window panel (as shown in Figure 5-1). After the rows are arranged, secure the upper part of the wall by using cable ties, and secure the front and side walls by using galvanized cable ties, as shown in Figure 5-2

图5-1

图5-2

6.Wall fix

Place five floors on the chassis purlins and clamp the boards on both sides at the same time (as shown in Figure 6-1). Hit 2.5 nails on the top of the upper buckle groove to stop down, and hit the frame on the side of the buckle groove with 7.5 self-tapping nails. The nail position is to ensure two nails on one board. Make the wall board, buckle groove, frame as a whole fixed. (As shown in Figure 6-2)

图6-1

图6-2

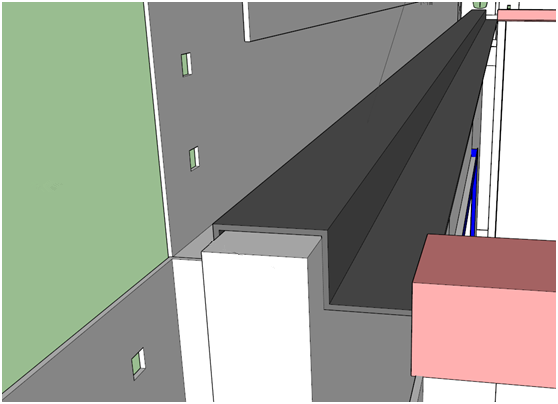

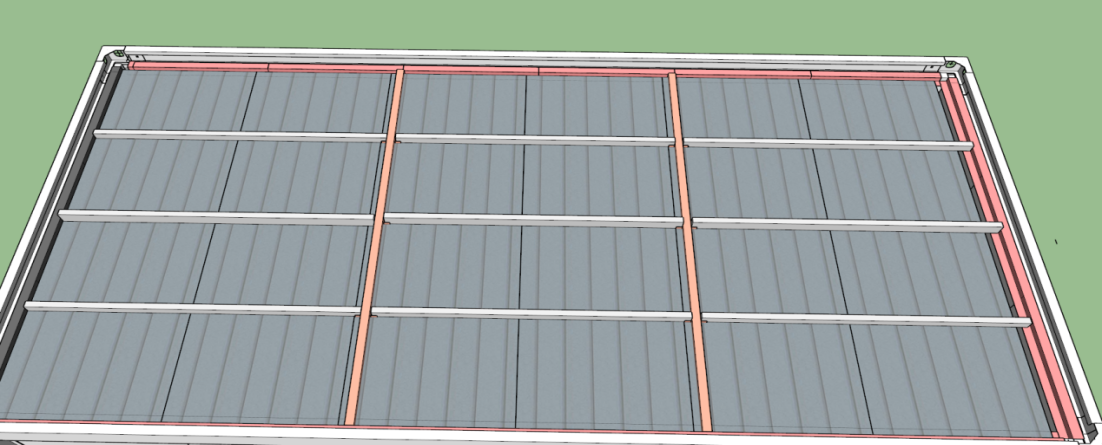

7,Top frame install

1)Bottom top frame install(inside ceiling)

Put 2pcs Roof panel put into the pressing plate As shown in Figure 7-1

图7-1

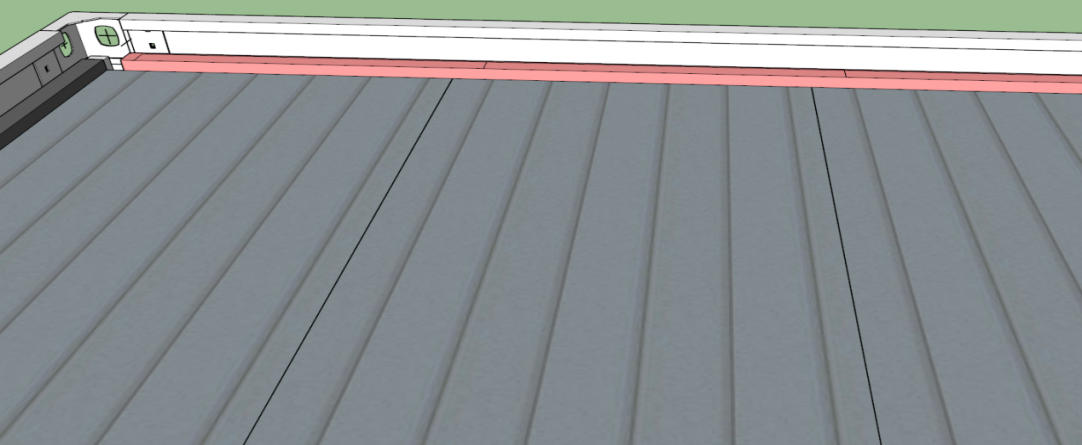

2)Install the roof purlin at the top of the roof. Use a self-tapping nail to push the corrugated bars at the contact position with the buckle of the wall body from bottom to bottom, and connect the bracket, indoor ceiling, and roof corrugated bars together, as shown in Figure 7-2

图7-2

3)After finish 1 and 2 process, cover with Glass cotton lap as shown in Figure 7-2

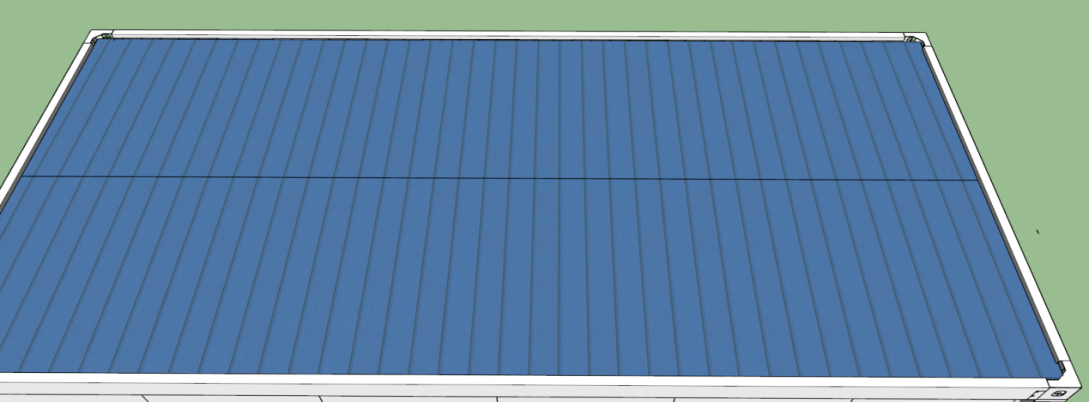

4)Lay the roof tiles and connect the roof tiles with the roof corrugated strips with 25mm self-tapping nails, as shown in Figure 7-3

图7-3

8)Roof panel install caution

Before placing the top tile, it is necessary to attach sealing strips to the outer eaves of the two six meter direction buckle slots, in order to prevent tile backflow. When the top tile is placed, it is necessary to highlight the top frame guide sink mouth 2 cm, and then separate a flat wheel flap with 2.5 self-tapping nails to stop the buckle groove, and pay attention to the tile and tile lap need to apply a section of waterproof glue, but also to prevent tile drainage water droplets back into the room. Finally, apply waterproof structural adhesive on the top of the nail.